What Are The Best Materials For Rigid Boxes?

Choosing the right material feels overwhelming. A wrong choice can make your luxury product look cheap. The best material is a perfect match between a strong inner core and a beautiful outer wrap.

The best material is a combination. It uses a thick, sturdy paperboard like chipboard for the core structure. Then, a decorative paper is laminated on the outside. This wrap paper1 is chosen based on your branding needs, such as printing quality, texture, and eco-friendliness.

When I see a client receive a sample box and they instinctively stroke the surface, I know we’ve made the right choice. Or when I notice a flight attendant carefully placing one of our boxes into an overhead bin, as if it were a precious item itself. These moments remind me that choosing a material isn’t just a technical decision; it’s an emotional one. The best material is one that makes your product speak. The best packaging creates an experience that makes the receiver almost reluctant to open it. If you are looking for that "reluctant to open" feeling, let’s explore how to achieve it.

What material is used for rigid boxes?

You hear "paperboard" but that term is vague. Using the wrong kind of paperboard can result in a box that feels weak. You need to know the specific components for a truly rigid box.

Rigid boxes are made from two key materials. The first is a thick, dense inner core called chipboard or greyboard for structure. The second is a thinner, decorative wrap paper that is glued and laminated to the outside for branding and visual appeal.

To get the best result, we must understand the two parts of a rigid box: the skeleton and the skin. This clarity is crucial when I work with professional buyers like Anne, who need to ensure quality from a distance. The wrong choice in either part can compromise the final product, affecting everything from durability to brand perception. Let’s break down these two essential components.

The Core: The Box’s Skeleton

The core provides all the strength. It’s made from a very dense, non-bending paperboard, usually called chipboard or greyboard. This material is made from recycled paper pulp that has been compressed into a thick sheet. It is not designed to be pretty; it is designed to be strong. The thickness is the most important factor here. A thicker core means a stronger, heavier, and more premium-feeling box2. The selection of the right thickness directly impacts the box’s structural integrity and its ability to protect the product inside, especially during shipping.

| Chipboard Thickness | Recommended Use |

|---|---|

| 1.5 mm | Small, lightweight items (e.g., small jewelry, USB drives) |

| 2.0 mm | Medium-sized items (e.g., candles, cosmetics, smaller electronics) |

| 2.5 mm | Larger products (e.g., shoes, skincare sets) |

| 3.0 mm | Heavy or high-value items (e.g., spirits bottles, luxury electronics) |

The Wrap: The Box’s Skin

The wrap paper is what your customer sees and touches. This is where your brand comes to life. This paper is laminated onto the chipboard core. You can choose from a huge variety of papers to achieve the exact look and feel you want. This layer carries your printed design, your logo, and any special finishes like embossing or foil stamping. The wrap is not just decoration; it’s a key part of the unboxing experience, communicating brand quality before the product is even revealed.

What paper is best for rigid boxes?

There are so many paper choices, and it’s easy to get confused. Choosing based on looks alone can cause problems with printing or durability. The best paper aligns with your specific brand goals.

The best wrap paper depends on your objective. Coated art paper is best for high-quality, vibrant photo printing. Textured specialty paper is best for a tactile, luxury feel. Kraft paper is best for an eco-friendly, natural aesthetic.

For my clients, choosing the wrap paper is the most exciting part. It’s where we translate brand strategy into a physical experience. Do you want sharp, colorful graphics that pop? Or do you want a subtle, elegant texture that whispers "quality"? Your answer determines the best paper for you. For a purchasing manager like Anne, balancing brand image, cost, and sustainability is key. This is a choice that has to be right. A cosmetics brand might choose a pearl-finish paper, while a tech company may prefer a sleek, matte black wrap. Every choice tells a story.

Let’s break down the most common options:

| Wrap Paper Type | Best For | Considerations |

|---|---|---|

| Coated Art Paper | Vibrant, full-color printing and photos. | The smooth surface is excellent for print detail but can show fingerprints. It can be coated with matte or gloss lamination for protection and effect. |

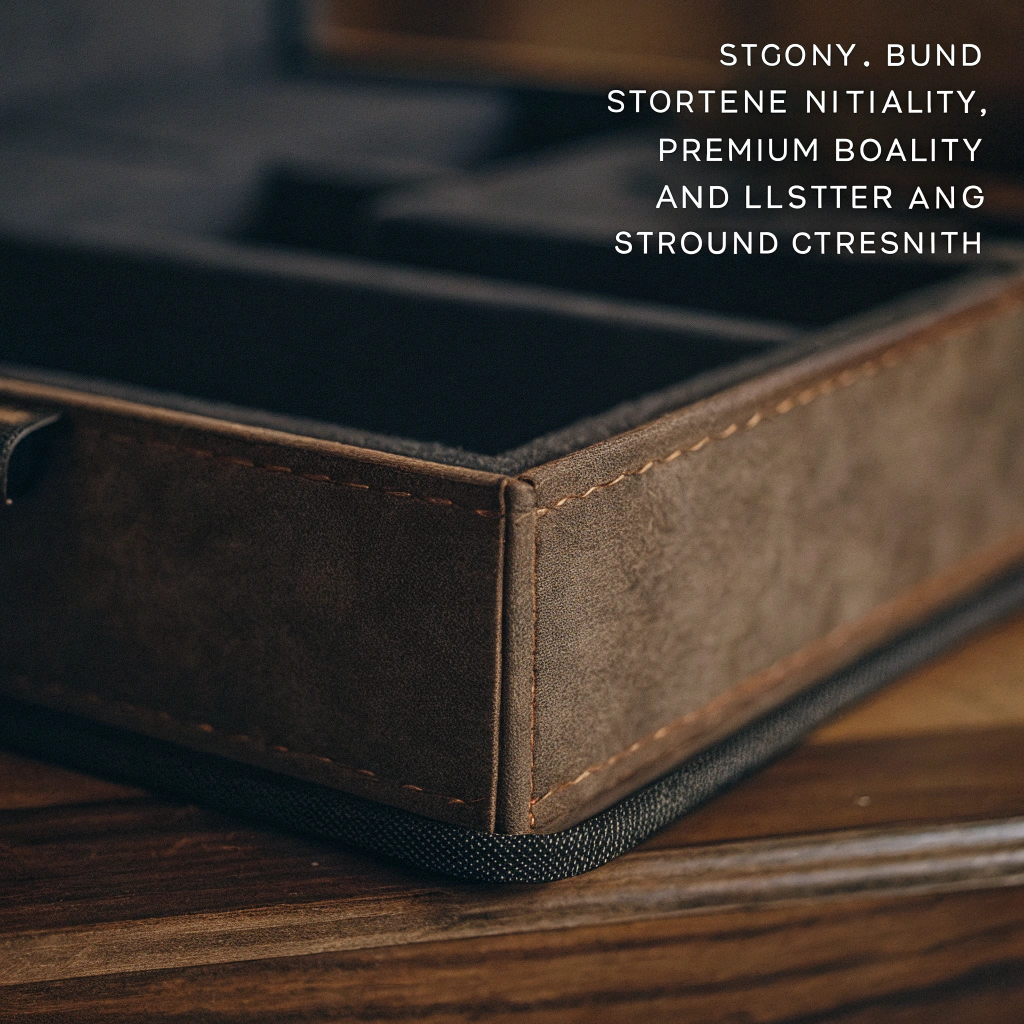

| Specialty Paper | Creating a unique tactile experience. | Comes in many pre-dyed colors and textures (linen, leatherette, etc.). Printing can be more challenging and costly. |

| Kraft Paper | An earthy, eco-friendly, and rustic look. | Great for sustainable brands. The natural brown or white color provides a distinct canvas. Print results are more muted. |

| Foil Paper / Fabric | Ultra-premium, high-end luxury products. | Foil paper gives a metallic shine. Fabric wraps (like silk or velvet) offer unmatched softness and luxury. This is the highest cost option. |

So, if you are an e-commerce brand with bold, colorful branding, coated art paper with a matte laminate is a fantastic choice. If you are an artisanal food producer, Kraft paper might perfectly communicate your natural-ingredient philosophy. For a high-end watch, a textured specialty paper or even a fabric wrap is what creates that unforgettable moment.

How to wrap a rigid box?

You have your core and you have your wrap paper. But how do they come together? A bad wrapping job creates bubbles and misaligned edges, ruining the premium effect completely.

Wrapping a rigid box is a precise manufacturing process. First, adhesive is applied to the printed wrap sheet. Then, a machine accurately places the chipboard core onto the sticky sheet. Finally, the machine folds and tucks the paper edges tightly around the box, creating seamless corners.

This process is a mix of art and science. I’ve spent years perfecting it with my factory partners. While it can be done by hand for very small quantities, achieving perfect consistency for a large order requires specialized machinery. This automation is what allows buyers like Anne to trust that every single box in a shipment of thousands will meet her brand’s high standards. Even a tiny mistake can reduce the perceived value of the product inside.

Here’s a simplified breakdown of the automated process:

- Printing & Cutting: Your design is printed onto large sheets of wrap paper. A die-cutter then cuts them to the exact shape needed to wrap the box, including flaps for the edges.

- Gluing: The cut sheets travel on a conveyor belt, and a roller applies a thin, even layer of glue to the back of each sheet.

- Spotting: This is the most critical step. A robotic arm or sensor places the flat chipboard core precisely onto the center of the glued wrap paper. An error of even a millimeter here will result in a crooked wrap.

- Wrapping & Folding: The machine then systematically folds the extending paper flaps up and over the sides of the chipboard. It uses pressure and heat to press the paper down, removing any air bubbles. Then, it carefully tucks and folds the corners for a sharp, clean edge.

The quality of the glue, the precision of the spotting machine, and the skill of the operator all contribute to the final result. This is why partnering with an experienced supplier is so important. A perfectly wrapped box has no bubbles, tight corners, and edges that meet flawlessly. It’s a small detail that makes a huge difference in perceived quality.

Conclusion

The best material is not a single choice, but a thoughtful combination. A strong core gives it structure, while the right wrap paper gives your brand a voice and an emotional connection.

.png)

-1024x802.png)

-1024x802.png)