How can you get the best packaging boxes at a cheap price?

You need quality packaging, but your budget is tight. Sourcing cheap boxes often leads to poor quality that damages your products and brand reputation. Finding the balance feels impossible.

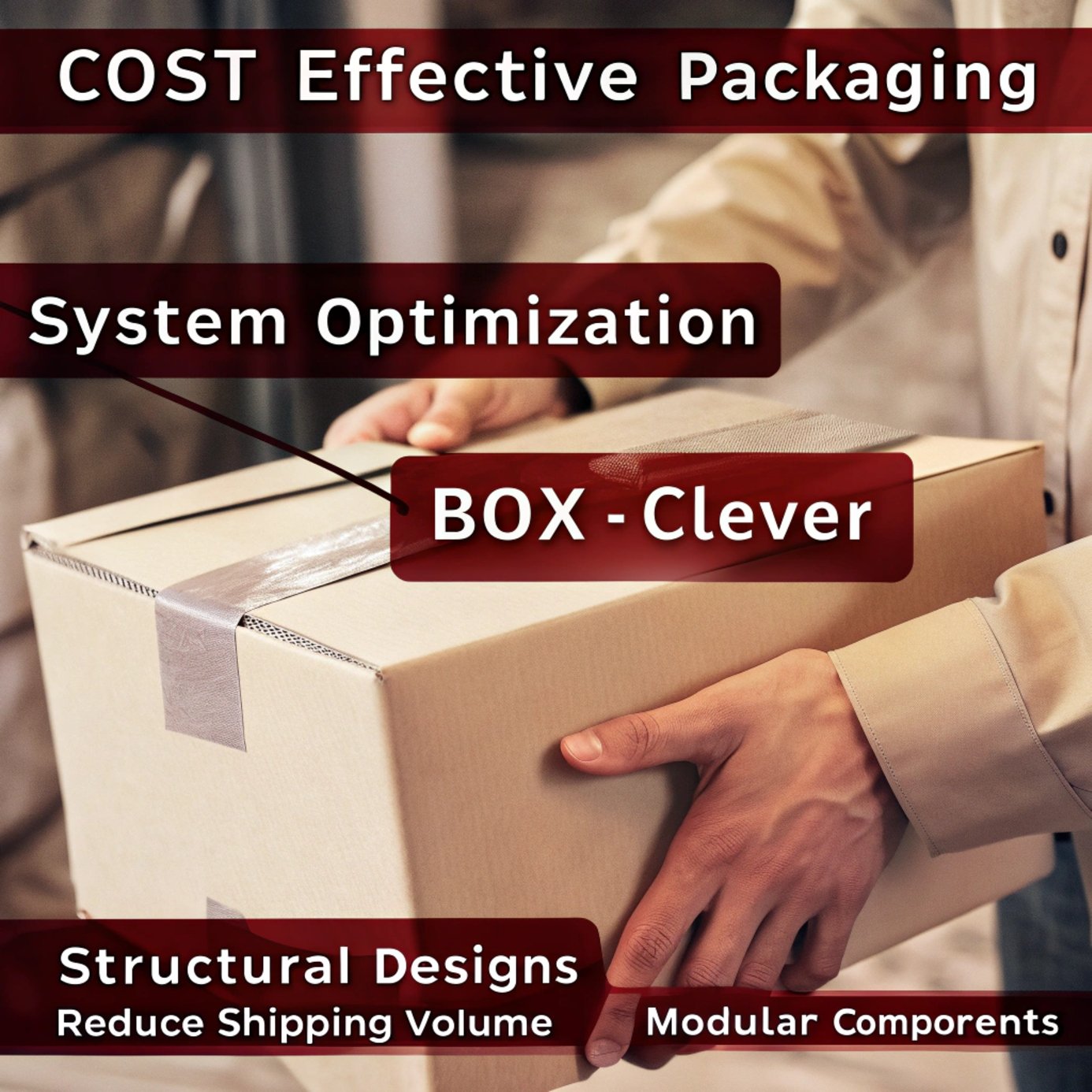

The best way to get quality boxes cheaply is not by finding the lowest price per unit, but by optimizing the entire packaging system. Smart structural design, efficient processes, and clever logistics can drastically reduce your total costs without sacrificing quality.

The search for a "cheap price" can be misleading. I’ve learned that the lowest number on a quote is rarely the best value in the long run. Real savings come from a smarter, more holistic approach. A great partner doesn’t just give you a price; they find you hidden savings throughout your entire process. Let’s look at how to achieve true cost-effectiveness without compromising the quality your brand deserves.

Is there a secret to finding the most cost-effective packaging1?

You’re constantly being asked to cut costs. But cheap materials can make your premium product look ordinary and lead to damage. How can you save money while still protecting and elevating your brand?

The most cost-effective packaging1 is a result of system optimization, not just material cost-cutting. This involves clever structural design to reduce shipping volume2, simplifying finishing processes, and creating modular components to decrease inventory complexity.

I worked on a project for an Australian health products company that perfectly illustrates this. Their goal was a 30% cost reduction, which seemed impossible without making the packaging look cheap. Instead of just quoting a lower price, we looked at their whole system. We called this our "Value Optimization" process. By focusing on smart changes instead of just cheaper materials, we not only met their goal but actually improved their packaging’s perceived value. This experience taught me a crucial lesson: the biggest savings are often hidden in plain sight, within the design and logistics, not just the supplier’s price tag.

Let’s explore how we achieved this:

- Structural Magic: The first thing we did was analyze the box structure itself. We found that by reducing the box height by just 5 millimeters, we could fit significantly more units into a shipping container. This small change saved them 17 cubic meters of shipping space annually, a massive saving on freight costs.

- Process Subtraction: The original design called for expensive hot foil stamping. We suggested switching to a deep debossing technique. The final look was just as elegant and premium, but this simple change in craft reduced the finishing costs by 40%. The customer got a similar high-end effect for a fraction of the price.

How can smart design choices save money on materials and shipping?

You have many different products, each needing its own box. This means high SKU counts, complex inventory management, and increased costs for tooling and storage. Can you simplify this without a one-size-fits-all solution?

By developing modular and adjustable components, like internal trays, you can use the same outer box for multiple products. This drastically cuts down on the number of unique box sizes (SKUs) you need to produce and manage, leading to significant savings.

For my Australian client, managing inventory for their wide range of bottle sizes was a major headache and expense. Every product had a unique box. Our solution was to design a single, elegant outer box and create a set of adjustable internal trays. This modular design was a game-changer. It allowed them to use the same packaging for dozens of different products, simply by changing the insert. This consolidation strategy was incredibly effective and shows how thinking inside the box can lead to big savings. True cost optimization comes from making your packaging work smarter, not just cheaper.

Let’s break down the impact of this modular approach:

- SKU Reduction: This was the biggest win. By creating adjustable inserts, we reduced their packaging SKU count by a staggering 70%. This meant less money tied up in inventory, simplified warehouse management, and fewer production runs.

- Tooling Savings: Fewer unique box designs mean fewer cutting dies and printing plates are needed. This significantly lowers the initial setup costs for production.

- Flexibility: They could now launch new products or change bottle sizes without needing to design and order completely new packaging from scratch, making them much more agile in the market.

Where is the cheapest place to get boxes made and assembled?

You’ve found a low price for boxes, but the costs add up. High labor costs for assembling the boxes at their destination can erase any initial savings. Is there a way to manage total cost better?

Sourcing from a country with lower production costs, like China, and having the supplier pre-assemble the boxes is often cheapest. This tactic leverages lower labor rates for assembly, saving you significant money compared to assembling them in high-wage countries.

This was the final piece of the puzzle for our Australian client. Assembling flat-packed boxes in Australia was expensive due to high local labor costs. We proposed a new strategy: we would handle 80% of the assembly here in our facility in China. The boxes would arrive practically ready to go, needing only the final product insertion. This shifted a significant portion of the labor cost from a high-cost environment to a lower-cost one. This pre-assembly strategy alone was a huge financial win and emphasizes why you must look at the total landed cost, not just the factory price.

Here’s why this strategy is so powerful for brands like Mike’s, who need to manage costs for US and EU markets:

- Lower Labor Rates: We completed the most time-consuming parts of the assembly at a much lower labor cost.

- Reduced On-Site Labor: Their team in Australia could pack products faster, with less manpower needed for tedious box folding.

- Faster Time-to-Market: With assembly already done, they could get their products onto shelves much more quickly after the shipment arrived.

In the end, by combining all these system optimizations, the client’s total packaging cost dropped by 31%, and the packaging quality actually went up.

Conclusion

True savings on packaging come from smart system optimization, not just squeezing suppliers for the lowest price. A good partner helps you find value in design, process, and logistics.