What Are the Benefits of Custom Magnetic Closure Boxes?

Your packaging gets thrown away just moments after opening. This means you lose a huge opportunity to make a lasting impression, turning your investment into trash.

Custom magnetic closure box1es elevate your brand with a premium feel and satisfying ‘snap’ closure. They are highly durable and reusable, turning simple packaging into a keepsake that keeps your brand visible and strengthens the customer’s unboxing experience long after the sale.

I recently got an email from a client in Germany. He attached a faded photo of a magnetic box we made for him back in 2017. The box was still on his daughter’s dressing table, and he mentioned that the lid still opened and closed as smoothly as it did on day one. He wrote, "This box has watched my daughter Lisa grow from a girl into a bride over seven years. Every time I hear that familiar ‘click,’ it feels like a promise of protection that never changes." That story gets to the true value of a magnetic box. It uses simple engineering to create a warm feeling and holds memories in its details. In a world of disposable products, packaging that someone cherishes for years is the best statement of quality you can make.

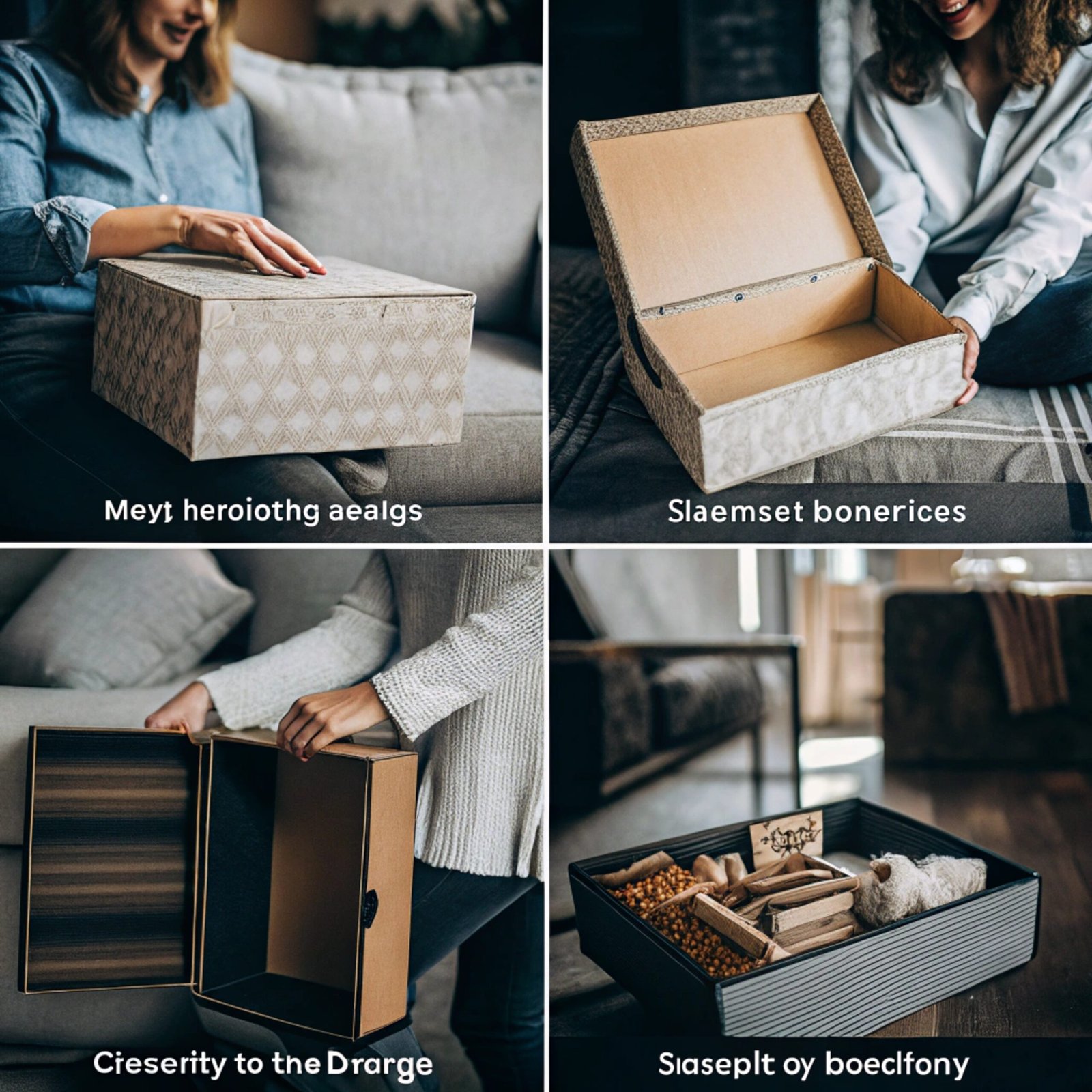

What exactly is a magnetic closure box?

You have seen these elegant boxes but might not know the term. This makes it hard to find them or explain why you want them for your product. It’s a box that feels different.

A magnetic closure box, or magnet box, is a type of rigid gift box with small, powerful magnets hidden inside the lid and front wall. These magnets create a secure, satisfying snapping sound and feel when the box is closed, offering a premium experience without needing ribbons or latches.

The magic is in the construction. These aren’t your typical folding cartons. They are built around a sturdy core, which gives them their rigid shape and protective qualities. The design is both elegant and clever.

The Anatomy of a Magnetic Box

The core of the box is made from thick, non-bending paperboard, often called greyboard. This structure is then wrapped in a paper of your choice, which can be printed with your designs and branding. The most important part is the set of small, neodymium magnets2. We carefully embed these magnets into the board of the lid flap and the front wall of the box base. When the lid comes down, the magnets attract each other, pulling the box shut with a crisp, audible "snap." This sensory feedback—the sound and the feel—is a huge part of what makes the unboxing experience feel so luxurious and high-end. Many of these boxes are also designed to be shipped flat for my clients, which dramatically reduces shipping costs and storage space before they are assembled.

How durable are magnetic boxes?

You worry that investing in premium packaging is a waste if it breaks. A flimsy luxury box can damage your product and your brand’s reputation for quality. These boxes are built to prevent that.

Magnetic boxes are extremely durable. Their construction uses thick, rigid paperboard that resists crushing and bending. The permanent magnets are designed for thousands of open-and-close cycles, ensuring the closure mechanism works perfectly for years, making them ideal for reuse.

When my German client told me about his daughter’s seven-year-old box, it wasn’t a surprise. We design them for that kind of longevity. The durability comes from materials and precision engineering working together. The rigid board we use is typically between 1.5mm and 3mm thick, much stronger than the paperboard used for a standard folding carton. This strength is why people keep them. They feel valuable and useful. The box becomes a storage case for jewelry, documents, or other keepsakes.

Built to Last: More Than Just a Box

The box on that bride’s dressing table wasn’t an accident; it was the result of specific quality choices. Here’s what makes them so tough:

| Component | Our Quality Standard | Result for You |

|---|---|---|

| Structure | High-density rigid board (min. 2mm) | Resists crushing during shipping |

| Magnets | N35 Grade Neodymium Magnets | Secure closure for 5,000+ cycles |

| Wrap | Anti-scuff laminate finish | Protects branding from wear and tear |

| Assembly | Machine-calibrated magnet placement | Ensures a perfect, crisp snap every time |

This focus on durability directly transforms a packaging expense into a long-term marketing asset. Every time your customer reuses the box, they are reminded of your brand and the quality you stand for.

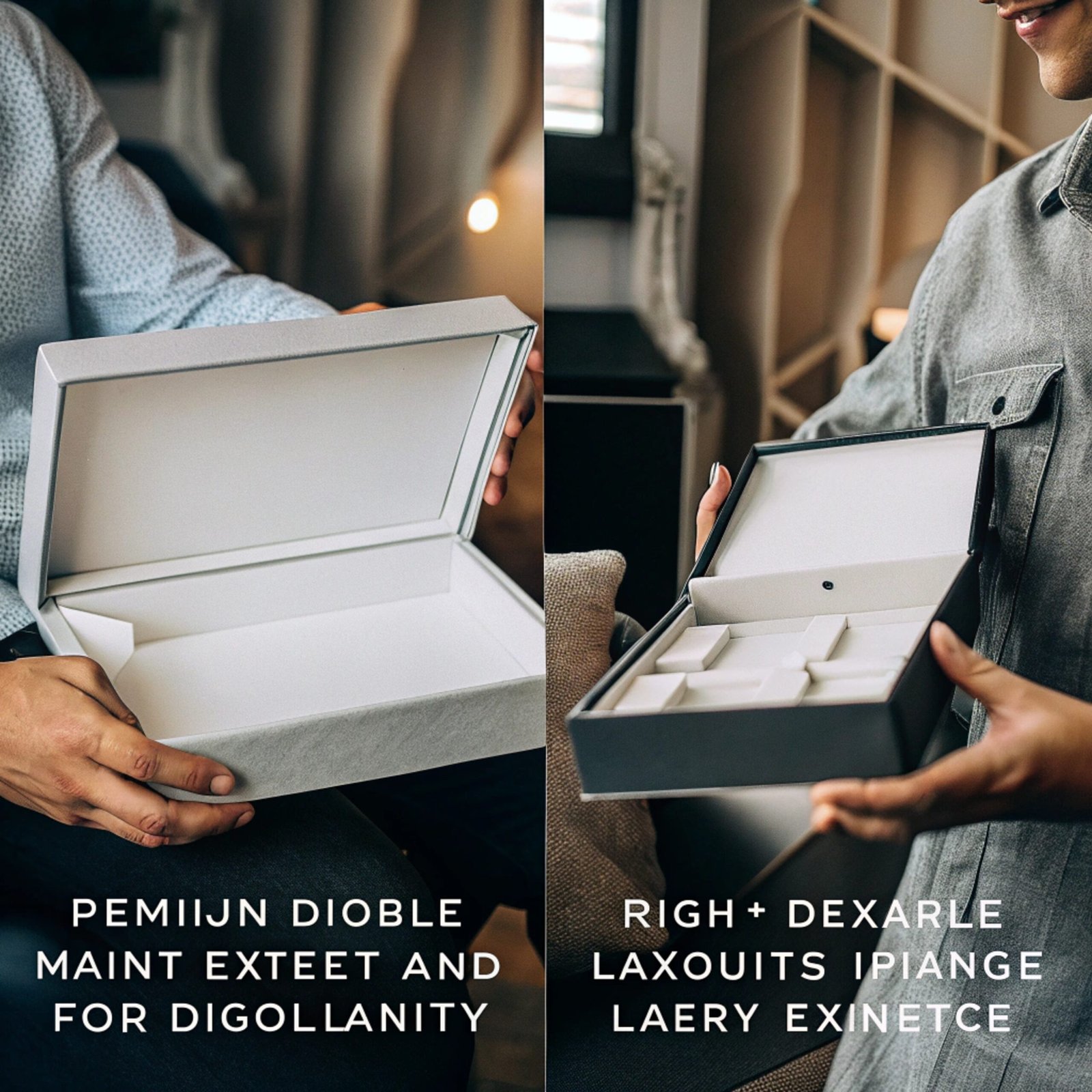

Can I customize magnetic gift boxes?

You want packaging that represents your unique brand, not a generic solution. An ordinary-looking box can make your premium product feel less special and not worth the price.

Yes, magnetic boxes are fully customizable. This is one of their greatest strengths. You can specify the exact size, print any color or design, and add special finishes like foil stamping. You can also customize the inside with inserts to hold your product perfectly.

A magnetic box starts as a blank canvas waiting for your brand’s story. For a purchasing manager like Anne, the ability to control every detail is critical to matching the packaging to her brand’s high standards in the US and EU markets. Customization is how we turn a simple box into a powerful brand statement. The options go far beyond just printing a logo. You are in control of the entire sensory experience, from the texture of the paper to the way your product is presented inside. This control allows you to create packaging that feels like a natural extension of the product itself.

Your Brand’s Story, Made Tangible

We can adjust almost every aspect of the box to align with your brand identity and product needs.

| Customization Area | Popular Options | Impact on Brand |

|---|---|---|

| Exterior Finish | Matte/Gloss Lamination, Soft-Touch, Linen Texture | Creates a specific tactile feel (e.g., modern, classic) |

| Branding | Foil Stamping, Embossing/Debossing, Spot UV | Highlights your logo with a luxury look and texture |

| Interior | Custom Color Printing, Printed Messages | Continues the brand experience inside the box |

| Product Fit | Custom Foam, Paperboard, or Fabric Inserts | Secures product perfectly and presents it beautifully |

These details work together to increase the perceived value of your product. When a customer receives a box that is so well-crafted, they inherently trust that the product inside is of equally high quality. This justifies a premium price point and builds strong brand loyalty.

Conclusion

Magnetic closure boxes are much more than just a container. They are a durable, fully customizable, and memorable experience that builds lasting brand value and turns customers into lifelong fans.